Origami robot devices combined in modular systems at Switzerland’s EPFL could vastly increase the number of tasks undertaken by robots.

“We are moving to the next generation of origami robots that are easy to manufacture, mass produceable. We want them to communicate with each other so that they can create different workforce tasks under a remote environment where normal robots or larger robots or more expensive robots have difficulty to get into,” Jamie Paik, director of EPFL’S reconfigurable robotics Lab (RRL), saying.

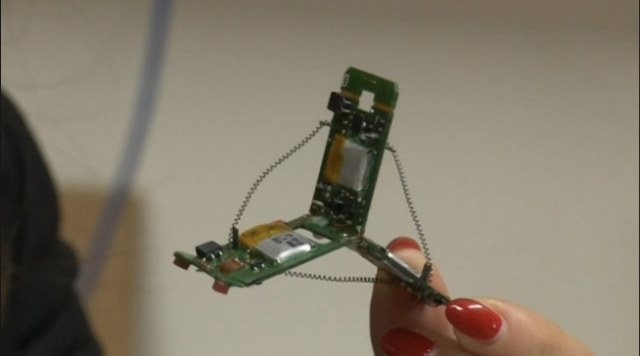

“They are made of multiple layers of flat sheet material and we fold them together to obtain a 3D shape of the robot. Then we introduce other components, like electronic components for sensing and communication, as well as a battery for powering on-board,” Zhenishbek Zhakypov, PHD Student at EPFL, saying.

“You should not cry over lost robots or a broken one on the way. So we want this to be a cheap, easy, solution for transferring information and in order to do that you need these robots to also tell multiple modes of locomotion,” Paik, saying.

“This robot could be manufactured on demand, customised, and then thrown in very large quantities into a rescue or emergency mitigation scenarios, so that they can collect data and detect possible victims,” Zhakypov, saying.